2022/08/09

「OWACONいよいよ海外デビュー?! 伊・MAPEI Realtaに日本のバズプロダクト 【オワコン】 掲載されました!」

実はこの6月に海外デビューを果たしていたOWACONことオワコン(造粒ポーラスコンクリート)。原料供給をしてくれているMAPEIのMAPEI Realtaでもジョルジオ・フェラーリ博士により記事紹介されました。極東の島国で起きているイノベーションは世界市場を飲み込もうとしている。

MAPEI Realta オワコン掲載

⚫︎MAPEI Realta pdf:RM_INT_93_PDF_SITO.pdf ※33頁が記事

【参考】原文テキストデータ

OWACON - THE NEW TECHNOLOGY FOR CREATING PERVIOUS PAVING WITH RE-CON ZERO EVO.

Pervious concrete paving is a valid answer to the problem of waterproofing surfaces in urban settings and the subsequent risk of flooding, which is occurring more and more frequently due to intense rainfall caused by climate change.

Pervious concrete is made from cement and coarse aggregates without sand and it is characterised by 15% to 25% of voids to allow water to drain off, permitting a drainage rate of between 100 and 300 litres/minute per square metre. These characteristicsallow rainwater to pass through relatively easily and filter into the ground, thereby replenishing the water table and preventing run-off into surface water bodies. Pollutants are leached from surfaces and percolate into the ground where they are held to prevent them from polluting surface water bodies. In 2011 EPA, the United States Environmental Protection Agency, included pervious concrete in their list of Best Management Practices, or BMPs, for rainwater as an alternative to aerated ponds.

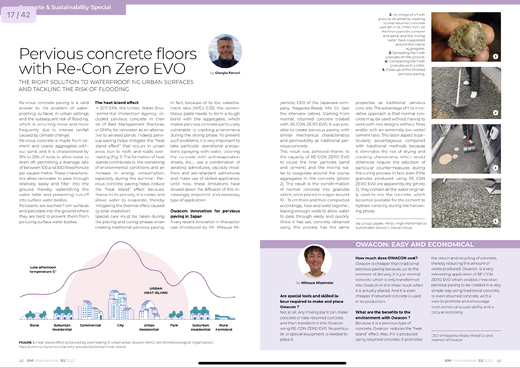

Another advantage of pervious paving is that it helps mitigate the "heat island effect" that occurs in urban areas due to roofs and roads overheating (Fig. 1). The formation of heat islands contributes to the worsening of environmental conditions and an increase in energy consumption, especially during the summer.

Pervious concrete paving helps reduce the "heat island" effect because, thanks to its porosity, it is cooler and allows water to evaporate, thereby mitigating the thermal effect caused by solar irradiation.

Figure 1. Heat island effect produced by overheating in urban areas. From "WMO, World Meteorological Organization, https://community.wmo.int/activity-areas/urban/urban-heat-island".

Special care must be taken during the placing and curing phases when creating traditional pervious paving. In fact, because of its low water/cement ratio (W/C ≤ 0.35), the cementitious paste needs to form a tough bond with the aggregates, which makes pervious concrete particularly vulnerable during the drying phase to cracking phenomena. To prevent such problems it is very important to take particular operational precautions (spraying with water, covering the concrete with anti-evaporation sheets, etc.), to use a combination of aerating admixtures, viscosity modifiers and set-delay admixtures and to use skilled labour. Until now, these limitations have slowed down the diffusion of this increasingly important and necessary type of application.

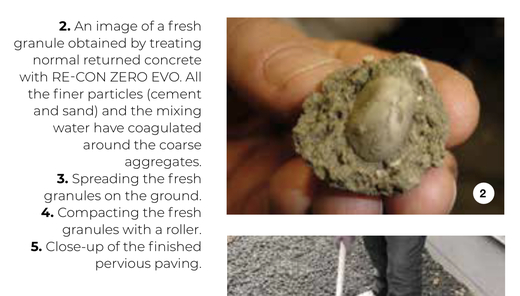

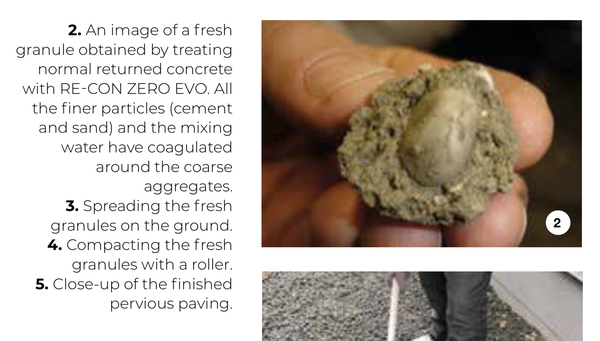

This result was achieved thanks to the capacity of Re-Con Zero EVO to cause the finer particles (sand and cement) and the mixing water to coagulate around the coarse aggregates in the concrete, as illustrated in the following image.

Fig. 3. An image of a fresh granule obtained by treating normal returned concrete with Re-Con Zero EVO. All the finer particles (cement and sand) and the mixing water have coagulated around the coarse aggregates.

The result is the transformation of normal concrete into granules which, once placed in a layer around 10 - 15 cm thick and then compacted accordingly, fuse and weld together, leaving enough voids to allow water to pass through easily and quickly. Once it has set, concrete obtained using this process has the same properties as traditional pervious concrete.

The advantage of this innovative approach is that normal concrete may be used without having to work with mix designs without fines and/or with an extremely low water/cement ratio. This latter aspect is particularly advantageous compared with traditional methods because it eliminates the risk of drying and cracking phenomena, which would otherwise require the adoption of particular countermeasures during the curing process. In fact, even if the granules produced using Re-Con Zero EVO are apparently dry (see Fig. 3), they contain all the water originally used to mix the concrete, which becomes available for the cement to hydrate correctly during the hardening phase.

We questioned Mr. Miyamoto about the process:

Q: Are special tools and skilled labour required to make and place OWACON?

A: Not at all. Any mixing plant can make concrete or take returned concrete and then transform it into OWAVON using Re-Con Zero EVO and no particular or special equipment is needed to place it.

Q: How much does OWACON cost?

A: OWACON is cheaper than traditional pervious paving because, up to the moment of delivery, it is just normal concrete which is only transformed into OWACON in the mixer truck when it is actually placed. And it is even cheaper if returned concrete is used in its production.

Q: What are the benefits to the environment with OWACON?

A: Because it is a pervious type of concrete, OWACON reduces the "heat island" effect. Also, if it is produced using returned concrete, it promotes the return and recycling of concrete, thereby reducing the amount of waste produced.

In conclusion, OWACON is a very interesting application of Re-Con Zero EVO which enables innovative pervious paving to be created in a very simple way using traditional concrete, or even returned concrete, with a view to promote and encourage environmental sustainability and a circular economy.

興味があったら上記を読んで英語の勉強をしよう笑。

【要約】既往のポーラスコンクリートになかった性能

で?結論は?って思ってる方々に先回りして要約を説明しよう。

ジョルジオ・フェラーリ博士はその段違いに改善された製造・施工性を取り上げている。

既往のポーラスコンクリート(オコシコン他)が有しているアドバンテージに加えて、施工簡易性(施工中の保湿性能)と製造簡易性(特殊配合ではなく生コンであればどんな配合でも適応可能)を挙げている。

こちらがオコシコン(既往のポーラスコンクリート)の構造。

写真では分かりにくいかもしれないが、粗骨材(砂利とか砕石とか)の周りにセメント+水がペースト状に被膜されている。

一方、オワコンは似たようなポーラス構造(おこし状)ではありながらもセメント+砂+水がペースト状で包んでいる。

オワコン脅威の施工性

つまり、セメント+水よりも水もちがいい「保水性」が特徴として挙げられる。

既往のポーラスコンクリートの場合施工中の熱射や風の影響で「すぐに乾いちゃう」という問題点があった。

一方、オワコンは全然乾かない。

急ぐ必要がない。

だって、時間に追われる必要ないから。

もちろん、オコシコン同様さっさと終わらせることだってできる。

施工者にとって非常に都合がいい。

これが、「オコシコンよりも施工が10倍楽!」と施工経験者を唸らせるオワコン最強の特徴。

DIYだってできちゃうくらいだからね。

で、もう一つ。

「生コンであれば全てオワコンにできる」

これ。

面倒なこと一切ない。

日本人の生コン屋さんならみんな知ってる 18-8-20/25(N/BB) とか標準的な配合を製造すればそれを造粒材でポーラスコンクリートにするだけ。

これ、元々 18-8-20(N) だったんだよー。

すごいでしょー。

実はOWACON今回が初めての海外デビューじゃない

Concrete production in Japan

Another application of Mapei product Recon Zero EVO evolved during the handling of granulates from dry-washing. As described before, granulates from dry-washing are discharged from the concrete mixer and let harden for approximately 24 hours or more and then crushed into so-called RCZ Aggregate. Japanese concrete plant Nr-mix produces "Owacon", granulated porous concreteinstead of RCZ Aggregate. Owacon started from the thought of processing the concrete left in the ready-mixed concrete truck that came back from the site. Owacon consists of 125 kg of cement, 2000 kg of aggregates (fine and coarse), approx. 125 kg of water and Recon Zero EVO. Everything is blended in the concrete truck on its way to the placement location. Granulated porous concrete is finished by compacting and among the other properties dispone by high permeability.

The idea of reduction of waste from concrete plants evolved even further and developed granZ concrete, granulated porous concrete with zero cement concrete, and slag aggregates in cooperation with Yokohama National University. GrandZ concrete is moving being tested on large scale after robust testing and development in the laboratory.

(Iveta Novakova from UiT The Arctic University of Norway)

⚫︎参考記事:《FIB Congress》「国際コンクリート連合に登場?! 【オワコン】【granZ concrete】 ついに、海を渡る!!」造粒ポーラスコンクリート

ほらね。

この6月に開催されてた国際コンクリート会議でも紹介されてたんだよー。

日本だけじゃない電気・水道・生コン供給網をオワコンが通る

MAPEIの供給網は世界全体に及んでいる。

そして、世界のいずれの地域にもおよそ必ず電気・水道・生コンの供給網が構築されている。

生コン工場はMAPEIの販売先となっている。

この流通を有するMAPEIがOWACONを見出した。

今は極東の島国で流通している生コンでしかないオワコンはやがて世界の地面を市場として普及を見ることになるだろう。

単なるポーラスコンクリートではない。

その販売・製造のノウハウは今国内のパートナーたちと共に醸成されている。

世界が日本を注目する日がやってくる。

断言しておきましょう。

お楽しみに。

おし、英語勉強しなおそ。

宮本充也

オワコン工事一式原価例

(生コンビニ仕入れ配送料無料)

◆施工面積40m2

| 材料費 (配送料無料) | 80,000円 | 40m2 x 0.05m(50mm厚) = 2m3 x 40,000円(単価) |

|---|---|---|

| 工事費 | 70,000円 | 2名 x 35,000円(日当) |

| 諸経費 | 7,500円 | 5% x (80,000円(材料) + 70,000円(工事)) |

| 合 計 | 157,500円 |

※単価:165,000円/40m2

= 3,938円/m2

◆施工面積60m2

| 材料費 (配送料無料) | 120,000円 | 60m2 x 0.05m(50mm厚) = 3m3 x 40,000円(単価) |

|---|---|---|

| 工事費 | 95,000円 | 2名 x 35,000円(日当) + 1名 x 25,000円(手許) |

| 諸経費 | 10,750円 | 5% x (120,000円(材料) + 95,000円(工事)) |

| 合 計 | 225,750円 |

※単価:225,750円/60m2

= 3,763円/m2

コンクリートをもっと身近に「生コンビニ」はこちら